- Home

- About

- News

- Products

- Download

- Jobs

- Support

- Message

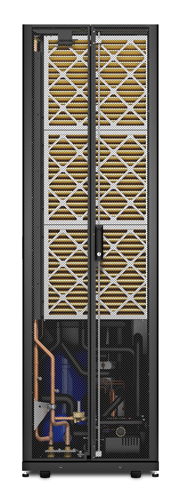

Product Name : ACRD602P

Product Name : ACRD602P

Item# : 212934-909

Model : 212934-909

Was Price: CNY0/pc

Now Price : CNY0/pc

Last update : 2016.12.31

Manufacturer :

InRow RD, 600mm Air Cooled, 380-415V, 50/60Hz, with humidifier

Includes: Door key , Installation guide , Integrated network management , Network Management Card , Operations and maintenance manual , User Manual

ACRD602PFeatures

InRow RD, 600mm Air Cooled, 380-415V, 50/60Hz, with humidifier

-

Active Airflow ControlMonitors and actively adjust cooling unit airflow in containment systems, while providing visibility to effective cooling to critical IT equipment.

-

Active response controlMonitors and actively adjusts cooling capacity to ensure proper server inlet temperatures. Through the microprocessor controller, visibility into the operation and status of the unit is provided.

-

Air filtrationRemoves dirt and other particulates from the intake air for cleaner supply air.

-

Architecturally neutralUnobtrusive design and coloring, blends in with the surroundings.

-

Capacity ControlCooling system will operate from 0 - 100% of the rated capacity to maintain rack inlet temperatures and reduce operational costs at varying heat loads.

-

CastersProvides flexibility to move the unit to wherever cooling is required.

-

Containment system compatibleThe unit can be combined with a Rack or Hot Aisle Containment System to eliminate hot air mixing and maximize cooling efficiency

-

Continuous current monitoringPermits a continuous monitoring of the compressor’s absorbed current to signal possible discrepancies with the default values (Optional).

-

Direct drive motorsStress on bearings is nearly eliminated, increasing useful life. Allows integral fan/motor assembly to be factory balanced, which lowers vibration and expedites startup.

-

Ease of UseSimplifies future planning by allowing side to side equipment to be placed anywhere in the data center.

-

Easy to installInnovative design allows for fast, easy installation by almost anybody.

-

EfficiencyIncreases the capacity of the air conditioner by supplying a warmer return air temperature.

-

Electric ReheatPrevents overcooling during dehumidification.

-

Electronic expansion valveRefrigerant flow optimization at any load and temperature conditions. Continuous indirect refrigerant charge monitoring

-

Electronically Commutated FansProvide the highest efficiency and reduce total power consumption by matching the airflow requirements to the heat load of the data center.

-

Enclosure system compatibleSpecifically designed to work with Netshelter Enclosures.

-

Fan guardsA safety measure that provides protection from the fan opening by covering the inlet.

-

Fault-tolerant fan systemIn the event of a fan failure, the remaining fan(s) will continue to operate.

-

Field replaceable componentsFans and electronics module can be readily replaced without uninstalling the unit.

-

FlexibilitySupport for varying aisle widths, rack heights, rack depths, and single rows. Supports hot and cold aisle containment

-

Front service accessThe system has full service, front access for routine servicing of components. Front access also narrows the footprint of the system making it possible for units to be placed side by side.

-

Green RefrigerantEnvironmentally friendly refrigerant that can offer LEED points.

-

Hardwire capableFor installations where hard wiring is required or prefered.

-

Head pressure controlModulates refrigerant head pressure to protect from coil freeze.

-

High Sensible-to-Total Cooling RatioAchieved by careful sizing of heat exchanger coils.

-

Horizontal airflow patternRemoves heat close to the source of generation in the hot aisle and distributes cold air to the front of the racks in the cold aisle.

-

HumidifierHumidity is managed through a self-contained steam canister humidifier for maximum efficiency and ease of maintenance. The pure steam canister maintains consistent capacity output, and requires very little or no scheduled maintenance.

-

Increased capacityHigher rate of heat removal allows more equipment to be installed in each rack.

-

Local area networkCreates a shared control between all the available resources for maximum energy efficiency and controlled management of the group during emergency situations

-

Minimizes Air MixingDelivers cool, conditioned air directly to the inlet of IT equipment.

-

Modular strategyModular design of the mechanical and control systems allow for gradual build-up of the cooling infrastructure to match the cooling demand of the facility. This greatly reduces CAPEX expeditures and provides deferred investment throughout the life of the facility.

-

Network interfaceProvides management by connecting the device directly to the network with a dedicated IP address, avoiding the need for a proxy such as a server. Management is available via Web browser, Telnet or SSH. Notification features inform you of problems as they occur.

-

Operational efficiencyWarmer entering air temperatures reduce both the required amount of humidification and the demand for costly reheat.

-

Predictable coolingPlacing the unit in the row of racks moves the source of cooling closer to the heat load. This eliminates air mixing and provides a predictable cooling architecture.

-

Predictive failure notificationMaximizes system availability by providing early warning of required fan or filter replacement.

-

Programmable input/output contactsAllows device contacts to be connected to the air conditioner and mapped to customer outputs or system alarms.

-

Rack Inlet Temperature ControlReduces the risk of hot spots at the rack level

-

Real-Time Capacity MonitoringReal-time display of current and available cooling.

-

Rear containmentEnsures server exhaust air is returned to the InRow cooling units for maximum cooling predictability.

-

Row-based architectureCaptures hot exhaust air directly from the IT equipment, thereby increasing the unit's sensible cooling capacity over traditional cooling architectures.

-

Scalable DesignModular design provides scalable solutions to add cooling as demand increases.

-

Small FootprintEfficient use of space with a small footprint provides the ability for the unit to be placed in a corner or even installed into a partitioned space.

-

Temperature DisplayMonitors and displays temperature to prevent overheating.

-

Touch-screen GUIEnables easy configuration, full monitoring, and event logging

InRow Direct ExpansionFeatures & Benefits

Agility

-

Scaleable densitiesAllows for higher densities to be achieved by integrating containment with room, row and rack cooling system architectures.

-

Modular designModular design provides scalable solutions to add cooling as demand increases.

Serviceability

-

Easy service accessAllows for all serviceable components to be replaced/maintained by easily accessible panels/doors.

Total Cost of Ownership

-

Variable speed fansVariable speed fans reduce energy consumption during off-peak cooling periods.

-

In-Row architectureCaptures hot exhaust air directly from the IT equipment, thereby increasing the unit's sensible cooling capacity over traditional cooling architectures.

Manageability

-

Real-Time capacity monitoringReal-time display of current and available cooling.

-

Microprocessor controllerUtilizes intelligent, active response control, and real-time monitoring. The system is controlled by a microprocessor providing high level control functionality and human interface via a four line, eighty character, alphanumeric display

-

Building management system integrationSend alarms and data points allowing you to manage critical building infrastructure from a single system.

Availability

-

Rack inlet temperature controlReduces the risk of hot spots at the rack level

-

Active response controlsMonitors and actively adjusts cooling capacity to ensure proper server inlet temperatures. Through the microprocessor controller, visibility into the operation and health of the unit is provided.

-

Predictable coolingPlacing the unit in the row of racks moves the source of cooling closer to the heat load. This eliminates air mixing and provides a predictable cooling architecture.

Input

-

Nominal Input Voltage400V 3PH

-

Input frequency50/60 Hz

-

Input ConnectionsHard Wire 4-wire (3PH + G)

-

Power Feeds1.0

-

Input Power20200.0Watts

Communications & Management

-

Control panelMulti-function LCD status and control console

-

Audible AlarmAudible and visible alarms prioritized by severity

Physical

-

Maximum Height1991mm , 199.1cm

-

Maximum Width600mm , 60.0cm

-

Maximum Depth1070mm , 107.0cm

-

Rack Height42U

-

Net Weight402.0kg

-

Shipping weight447.0kg

-

Shipping Height2166mm , 216.6cm

-

Shipping Width850mm , 85.0cm

-

Shipping Depth1137mm , 113.7cm

-

ColorBlack

-

Units per Pallet1.0

Environmental

-

Operating Environment-20 - 50 °C

-

Operating Relative Humidity5 - 95 %

-

Operating Elevation0-3000meters

-

Audible noise at 1 meter from surface of unit84.0dBA

Conformance

-

ApprovalsC-tick, CE, EAC

-

Standard warranty1 year (parts only), 1 year on-site repair or replace with factory authorized Start-Up

General

-

Air Discharge PatternsHorizontal

-

Air Flow1887.78lps

-

Amp Draw In-Rush28.0A

-

Compressor TypeScroll

-

Condensate Pump Capacity0.034lps

-

Humidification Value6.6pounds/hour

-

Intake AirRear Return

-

Return Diameter19.0mm

-

Supply Diameter19.0mm

-

| Clicks:Home | About Us | Contact Us | Site Maps

Copyright 2004-2014 Veiton Network Studio www.veiton.com All rights reserved

沪ICP备18015660号-1 Southidc Technical Support VeitonCMS V17

沪公网安备 31010502000199号

- About